Creating a watertight design for 3D printing requires a large volume of materials. This is the most reliable way to ensure watertight prints. This method requires a larger amount of filament than normal but you won’t be penalized for the extra time. It also eliminates the risk of misprints because the thick layers do not stretch or warp. If you are considering using a biodegradable filament, consider making sure it is soluble in water.

Lattice generation tools

Automated lattice generation tools for 3D printing can be used to create lightweight, highly functional parts. These parts can be used in many different applications, from jewelry to medical implants. The tools work by evaluating the forces applied to the model. Users can select which cell structure is best for their design. Lattices can also reduce the cost of the final product. A popular use for lattices is in metal 3D printing, where they help to achieve osseointegration, which is the process by which bone fuses with a 3D printed implant.

CAD software

There are several factors to consider when choosing a CAD software for 3D printing. CAD programs have varying levels of functionality and require a bit of practice to master. Choosing beginner CAD programs is a good idea as they will offer a simpler user experience and basic functionality. Advanced programs are generally more expensive and will have a higher learning curve, but will offer a greater range of capabilities. The best 3D printing software is the most flexible and can handle a variety of different models, from simple to complex assemblies.

Non-manifold geometry

Creating objects in 3D software can be problematic if you create non-manifold geometries. Such models do not contain a logically enclosed space and cannot be 3D printed. As a result, they often give incorrect volume calculations. Non-manifold geometry can be avoided by following some simple guidelines. Here are some of the most important things you need to know when dealing with non-manifold models.

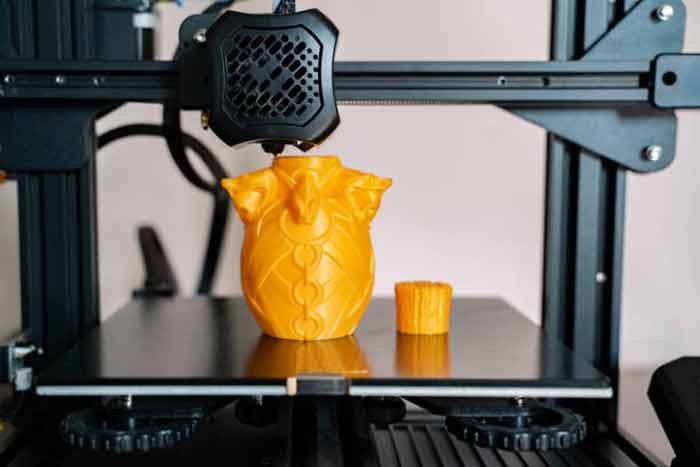

Objects printed in layers

Three-dimensional printing techniques, known as stereolithography and fused deposition modeling (FDM), produce three-dimensional objects by applying thin layers of photopolymer. The printers use UV light to harden the photopolymer, which forms a solid model. SLA printers build three-dimensional objects from top to bottom, while FDM printers use a thermoplastic that is heated to a melting point and extruded in layers.

Conclusion:

Among the different benefits of full-color 3D printing, a few stand out above the rest. For hobbyists, these machines can produce a range of objects, from scale models to fantasy figures. Others want to create decorative items or gadgets. In contrast, professional 3D printers are used to produce bulk quantities of items. The technologies used include Colorjet, full-color polyjet, and HP’s Multi-Jet Fusion.