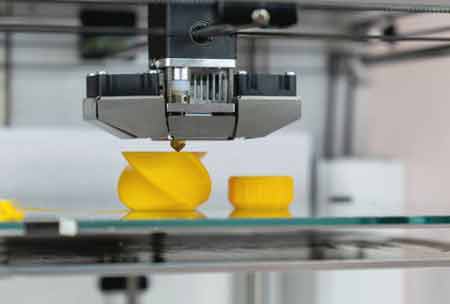

You might be wondering what exactly 3D printing is. The process is basically a way to create real-life objects from digital models. The process works like layering; you print one layer after another until you have the exact object you want. This is great news for DIYers, but it can also be a lot of work, especially if you are attempting to make a complex object. However, it is not as hard as it sounds. Here’s a quick overview of 3D printer.

What is a 3D Printer?

It is a type of manufacturing that allows you to make custom-made objects. The technology can create a variety of objects, from simple home accessories to car parts, as well as biomedical devices and biological organs. And because the process is so easy to use, even the most inexperienced people can make and modify these parts without any special training. When it comes to the materials that are available, PLA is the most common choice for beginners.

Flexible Manufacturing

Firstly, 3D printing is an extremely flexible method of manufacturing. It can produce intricate objects and prototypes in a fraction of the time and cost of traditional manufacturing methods. It is also very user-friendly, making it a popular choice for creating all kinds of products. For example, you can create a custom-designed toothbrush or a custom-made shoe mold if you have trouble finding a generic one.

Useful for Medical Purposes

Apart from making custom-made products, 3D printing can also be used for medical purposes. The technology is useful for creating hearing aids and artificial teeth. It can also be used to reproduce internal body structures from CT scans. A charity called Project Daniel, for example, uses 3D printers to create prosthetics for war victims in Sudan. The technology can also be used to create artificial organs and bones, which are useful for forensic purposes.

Types of 3D Printers

There are several different types of 3D printers. The newest models are made from ABS plastic. In addition to ABS plastic, 3D printing can use production grade plastics as well. This means that your parts can be made from various types of materials, ranging from plastics to non-plastics. There are also a number of other types of material that can be printed. Aside from plastics, 3D printers can also produce biological organs.

Custom Objects

Besides the advantages and disadvantages of 3D printing, it can be used for producing custom objects. These include home accessories, prototypes, and aerospace components. These materials are extremely flexible and can be designed to produce complex and unique objects. If you have an idea for a product, you can use a commercial 3D printer to create it. Its advantages are numerous. In fact, there are even several types of 3D printers, and there is a machine for every need.

Easy to Handle

A 3D printer will use the materials you choose. Its main advantage is that it is inexpensive and easy to handle. Most printers are compatible with the material, so you won’t have to worry about changing the shape of the parts. In addition to being affordable, 3D printing can also save the environment. A new type of manufacturing can be used to make custom-made objects, which can be used for many different purposes.

Conclusion

There are many applications for 3D printing, from prosthetics to home accessories. From car parts to biological organs, 3D printers can create everything from prosthetics to complex objects. Whether you want to make a sculptural part for a patient or for a professional, it can be helpful. If you’re a student, a smaller printer will be fine for your needs.