3D printing is a process in which an object or part, typically in plastic, is created by laying down successive layers of material. The 3D printer can create both 2D and 3D objects. It works by using computer modeling to create the desired object, and then sends this design to the printer that prints out the design one layer at a time. This process allows for previously impossible shapes that would be too complex or fragile to make with other methods.

What is a 3D Printer and How Does It Work?

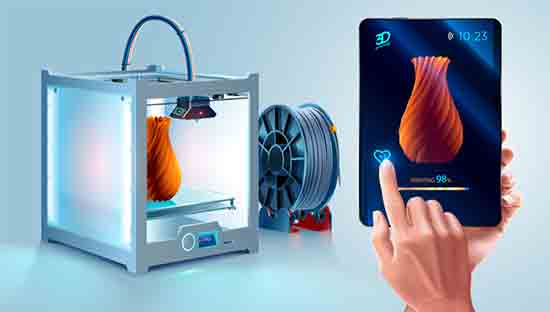

A 3D Printer is an additive manufacturing machine, which creates a three-dimensional object from a digital design.

The process begins by breaking the object into thousands of horizontal layers. This is done by transferring the digital design into a program, which then divides it into layers and calculates the amount of material needed for each layer. The object is then built one layer at a time, with each layer either being laid down or drawn out, until the object is completed.

3D Printing Technology Explained in Steps – From CAD to Finished Product

There are three principal stages in the 3D printing process:

– Design Data Creation

– 3D Printer Operation

– Finished Product Assembly

3D Printing starts with the design of the object to be printed. This is done by either modifying an existing design or creating an entirely new one. Designers use specialized software to create 3D models. Models are either made up of text or mathematical equations, but there are also different algorithms that make the content. These models are able to produce high-quality texts with limited input from you.

What Is The Difference Between FDM and SLA Printers?

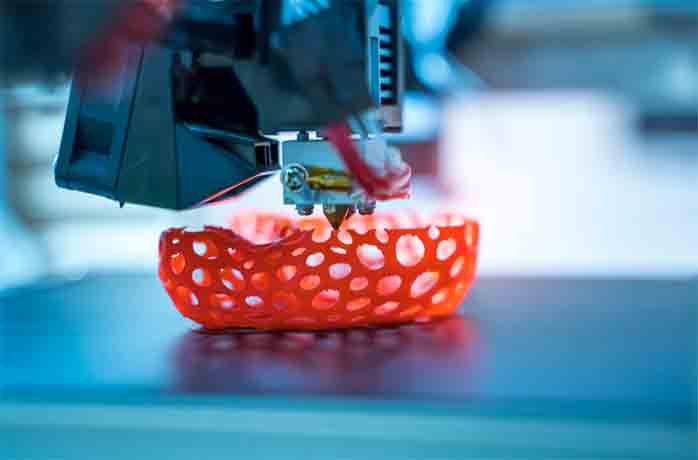

It is the newest type of industrial 3d printer. This printer starts with a wire feeder that deposits ABS or PLA plastic filament on a platform. It then uses a nozzle that extrudes melted plastic. The nozzle moves around the platform, depositing the material that builds the 3D object.

The material is deposited as layers. As the nozzle moves around the platform, it draws an outline of the cross-section of the 3D object that is being built.

A Beginner’s Guide to Making Your Own Creations on Your Home Maker Space

This guide is made for the individual who wants to make their own creations on their home maker space, but does not know how to get started. This guide will give you a list of materials and equipment that you will need to make your own creations.

The first thing you will need is a table that is not too high for you to work on. You can find tables that are adjustable or that can be lowered. For example, you can find electric tables that will stay at any height you want them to.

Conclusion

A 3D printer is a machine that assembles parts to create a three-dimensional object. A 3D printer has a spool of filament that feeds into the 3D printer head. The 3D printer head melts the filament, and then lays down successive loops of material, one layer at a time.